Youtube Laser Cutting

StarCut Tube Laser SL is the best laser cutting system for complex medical devices, such as stents and aortic valve replacements.

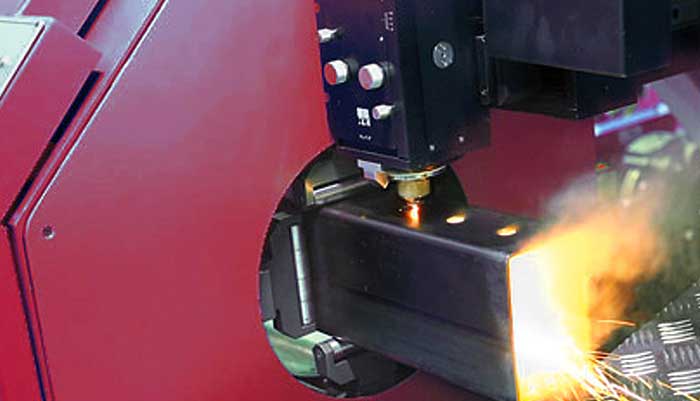

Fiber lasers can cut thin materials at high speeds. They are also very energy-efficient and require little maintenance. This laser cutting technology has special properties that allow for applications in steel, stainless steel, aluminum, as well as non-ferrous metals like copper and brass.